- Mini vmac install#

- Mini vmac full#

- Mini vmac plus#

If you are making the Mac Plus or the Classic:ĭriveSupport_front.stl. The fronts have extra supports in the design that will need to be removed after printing along with the generated supports. The fronts were printed upright with supports Everywhere.

Original Mac, Mac 128 or Mac Plus (the case looked the same)- front_plus.stl. front_supportTest.stl was printed with supports Everywhere. caseBack_supportTest.stl was printed with supports from the Build Plate Only. The toughest areas to support are the handle on the back and the details on the front with the disk opening and the slots for the SE and SE30 versions. There are 2 STLs used strictly to test supports. I arranged the back and front pieces so the support fins are oriented to make easy removal. I made a point to print it on the smooth plate. Sorry about the error.Īll parts were printed with a layer height of 0.20 in PLA. Important: I discovered an issue with misalignment of the screw hole in 2 of the fronts. The new ones will be up there soon as a remix of the original. If you have the old iUniker screen, those files are available on Thingiverse. There are also a couple of files you can use to test your supports without printing the entire part. I've also included the SketchUp file if you'd like to tweak the designs. I will plainly mark them for the Faux Disk and the SD card. Take a look at the instructions before deciding which build.īe aware of which case build you are following. For those of you with larger hands, V2 can be a little tricky to safely squeeze it all inside. The real difference in the build is the lack of space inside the case. The cost difference between the 2 versions is minor. It is inserted and removed similarly to a disk in real Mac Plus. Version 2 moves the SD card to the front of the Tiny Mac. Version 1 has a faux disk in the front of the Tiny Mac and the SD card accessible from the right side. You can now make a Mac Plus, SE, SE30 or Mac Classic. Mini vmac full#

Here's a full set of both Metric and US wrenches.Īll the STLs should be oriented properly on the build plate.

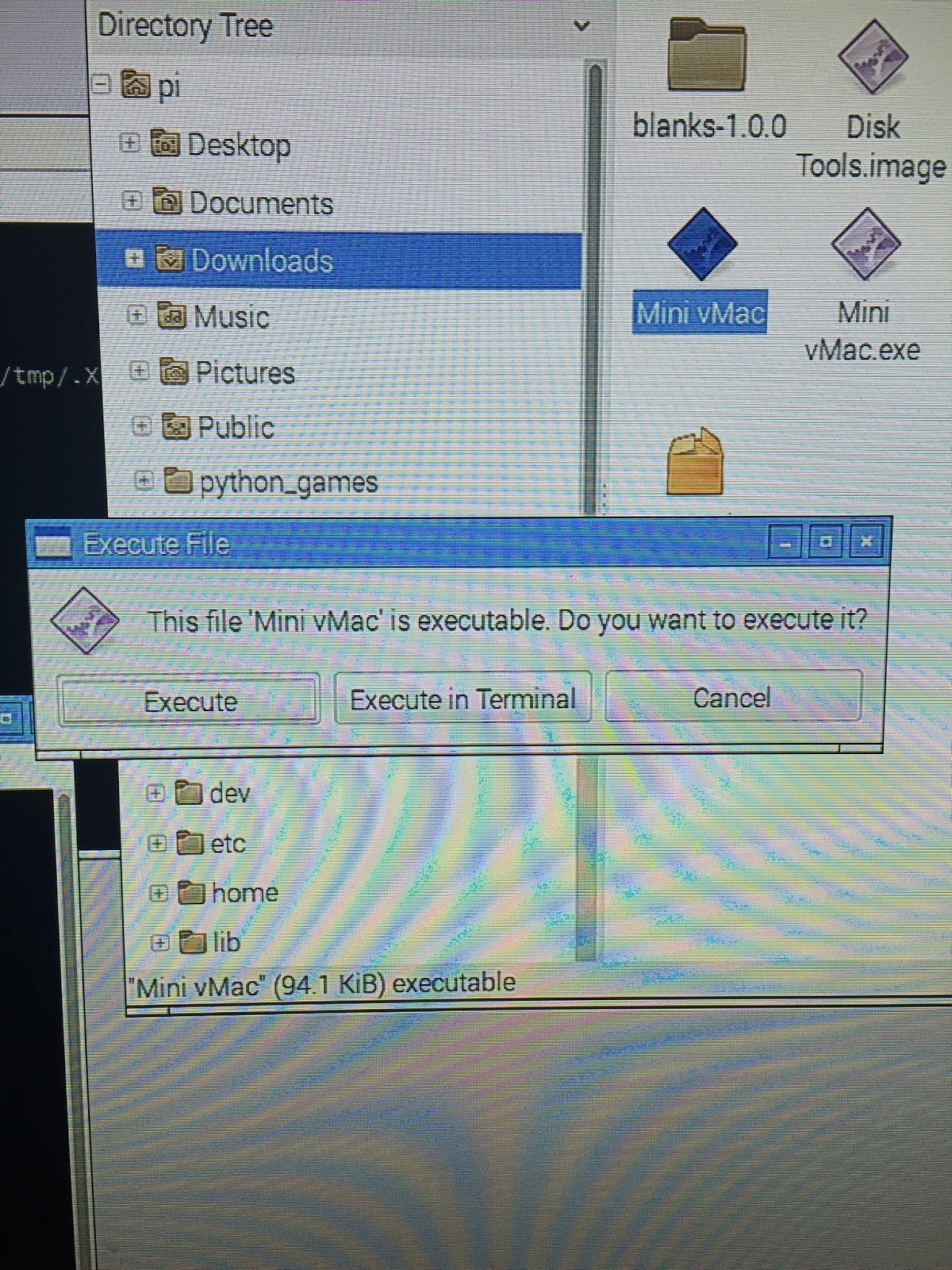

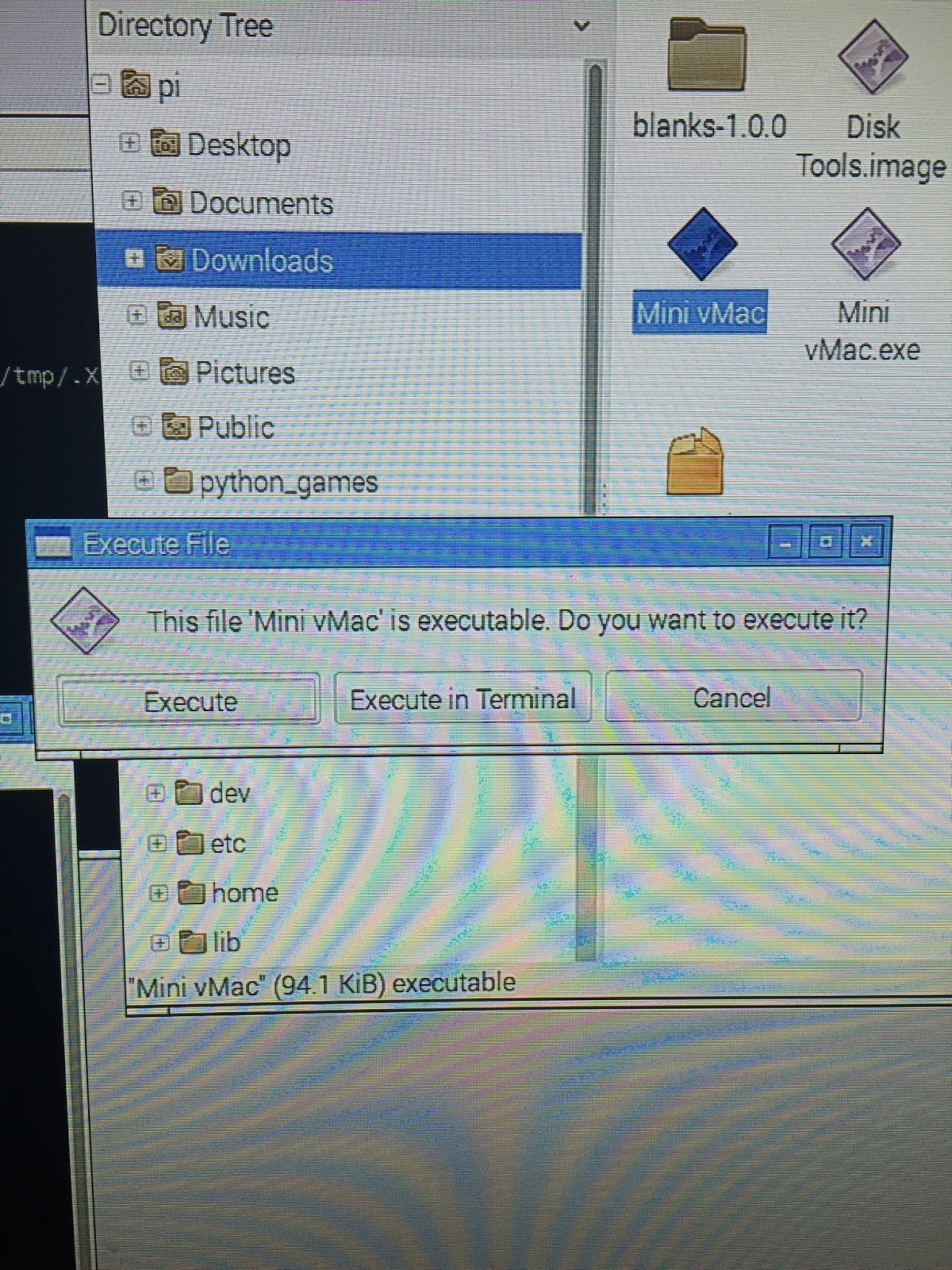

Blue Painter's Tape for Version 1 of the case. Platinum PLA Filament (hex code: #BFBCB1) for newer Macs – OR – Beige PLA Filament for the original Plus or 512k Macs (This information is thanks to the Macintosh Librarian). 3 - M3 X 12mm Hex Socket Head Cap Screws. You can use it to protect your Pi while configuring it. The small case is really not needed for the final project but is a nice to have. There are plenty of cheap options out there.Īmazon has a number of kits that include the above items. You can borrow a keyboard from your desktop. unless the applications you will be running need keyboard input. The keyboard is only really needed for setup. Anything much longer would be difficult to squeeze into the case. A SHORT GPIO 40 pin Male to Female ribbon cable. A Micro SD to SD Card Extension Cable Adapter Flexible Extender for Version 2 of the case. These can often be found as part of a starter kit. A mini HDMI to HDMI adaptor (for setup). A compatible power supply ( one with an integrated On/Off switch is a nice to have). Adafruit's estimate is $15 when they become available. If you search you will find them but way over priced. The instructions show the older model.) Note that these are in short supply and should be reasonably priced. Raspberry Pi Zero W OR Raspberry Pi Zero 2 W. Making a Small Mac from a Raspberry Pi 3. There is now a slightly larger Raspberry Pi 3x version available. If you are looking for the original STL files, they are available on Thingiverse. Mini vmac install#

If you need the to install software for the original iUniker screen, jump to Step 16. These instructions and models have been updated to support the Waveshare display.

Version 2 has the relocated SD card that is inserted in the front where the original Mac disk is.Ĭheck out the differences in Step 1. Version 1 has a Faux disk and the SD card is accessible from the right side. Note: The STLs are updated for use with an updated screen. All the other parts are readily available. You will need access to a 3d printer for the case. We will be using a 3d printed case I designed and build instructions of my own. Now you can make one for yourself! No soldering, no custom cable, no hand made case. I was able to make a smaller, cheaper and simpler version. Smaller, cheaper components and new fabrication methods have made the process far easier. Times have changed and technology has moved on. I really wanted one but didn't have the time or resources. He needed custom cables as well as solder work on the Pi. His was made from scratch from sheets of PVC, sanded and painted.

He made his before cheap 3d printers were everywhere. Years ago I saw that John Leake built a 1/3 scale Macintosh.

0 kommentar(er)

0 kommentar(er)